Spiral Submerged Arc Welded Pipe SSAW

Classification :

Carbon Steel Pipe

PRODUCT DETAILS

Keywords: Steel Plate 、 Steel Coil

Spiral Submerged Arc Welded Pipe SSAW Description

The spiral submerged arc welded pipe is made of hot-rolled steel strip as raw material, and is usually made by constant temperature spiral forming and automatic submerged arc welding. The manufacturing process is to roll the steel strip, make the rolling direction at a certain angle to the center direction of the tube, and then form and weld, so the weld is spiral. Can provide API SPEC 5L steel pipe, GB / T3091,GB / T9711-2011,EN10219,ASTM A252 standard steel pipe.

Product Parameters

|

Product Name |

Spiral Submerged Arc Welded Pipe SSAW |

|

Standard |

EN/DIN/JIS/ASTM/BS/ASME/AISI etc. |

|

Outer Diameter |

219.1mm-3580mm |

|

Wall Thickness |

3.2mm-25.4mm |

|

Length |

5.8 meters-12.5 meters, Support customization |

|

Manufacturing Type |

Spiral Welding |

Product Material

|

Standard |

Material |

|

GB/T3091 |

Q235B, Q345A, Q345B |

|

GB/T9711-2011 |

L210, L245, L290, L320, L360, L390, L415, L450, L485 |

|

API 5L PSL1 |

Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70, X80 |

|

API 5L PSL2 |

Gr.B, X42, X46, X52, X56, X60, X65, X70, X80 |

|

EN10217 |

P235TR1, P235TR2, P265TR1, P265TR2 |

|

ASTM A252 |

A252 Gr.2 , A252 Gr.3 |

Chemical Composition & Mechanical Properties

|

Standard |

Grade |

Chemical Composition(%) |

Mechanical Properties(min) |

|||||

|

C |

Si |

Mn |

P |

S |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

||

|

API 5CT |

h40 |

- |

- |

- |

- |

0.030 |

417 |

417 |

|

J55 |

- |

- |

- |

- |

0.030 |

517 |

517 |

|

|

K55 |

- |

- |

- |

- |

0.300 |

655 |

655 |

|

|

API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

335 |

335 |

|

B |

0.26 |

- |

1.20 |

0.030 |

0.030 |

415 |

415 |

|

|

X42 |

0.26 |

- |

1.30 |

0.030 |

0.030 |

415 |

415 |

|

|

X46 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

435 |

435 |

|

|

X52 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

460 |

460 |

|

|

X56 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

490 |

490 |

|

|

X60 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

520 |

520 |

|

|

X65 |

0.26 |

- |

1.45 |

0.030 |

0.030 |

535 |

535 |

|

|

X70 |

0.26 |

- |

1.65 |

0.030 |

0.030 |

570 |

570 |

|

|

API 5L PSL2 |

B |

0.22 |

0.45 |

1.20 |

0.025 |

0.015 |

415 |

415 |

|

X42 |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

415 |

415 |

|

|

X46 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

435 |

435 |

|

|

X52 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

460 |

460 |

|

|

X56 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

490 |

490 |

|

|

X60 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

520 |

520 |

|

|

X65 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

535 |

535 |

|

|

X70 |

0.12 |

0.45 |

1.70 |

0.025 |

0.015 |

570 |

570 |

|

|

X80 |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

625 |

625 |

|

|

ASTM A53 |

A |

0.25 |

0.10 |

0.95 |

0.050 |

0.045 |

330 |

330 |

|

B |

0.30 |

0.10 |

1.20 |

0.050 |

0.045 |

415 |

415 |

|

|

ASTM A252 |

1 |

- |

- |

- |

0.050 |

- |

345 |

345 |

|

2 |

- |

- |

- |

0.050 |

- |

414 |

414 |

|

|

3 |

- |

- |

- |

0.050 |

- |

455 |

455 |

|

|

EN10217-1 |

P195TR1 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

P195TR2 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

|

P235TR1 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P235TR2 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P265TR1 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

P265TR2 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10217-2 |

P195GH |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10217-5 |

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10219-1 |

S235JRH |

0.17 |

- |

1.40 |

0.040 |

0.040 |

360 |

360 |

|

S275JOH |

0.20 |

- |

1.50 |

0.035 |

0.035 |

410 |

410 |

|

|

S275J2H |

0.20 |

- |

1.50 |

0.030 |

0.030 |

410 |

410 |

|

|

S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

470 |

470 |

|

|

S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

|

|

S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

|

Scope of Application

Petroleum and natural gas industry, chemical industry, power industry, flammable liquid and incombustible liquid pipeline and building structure, water supply and drainage engineering, urban construction.

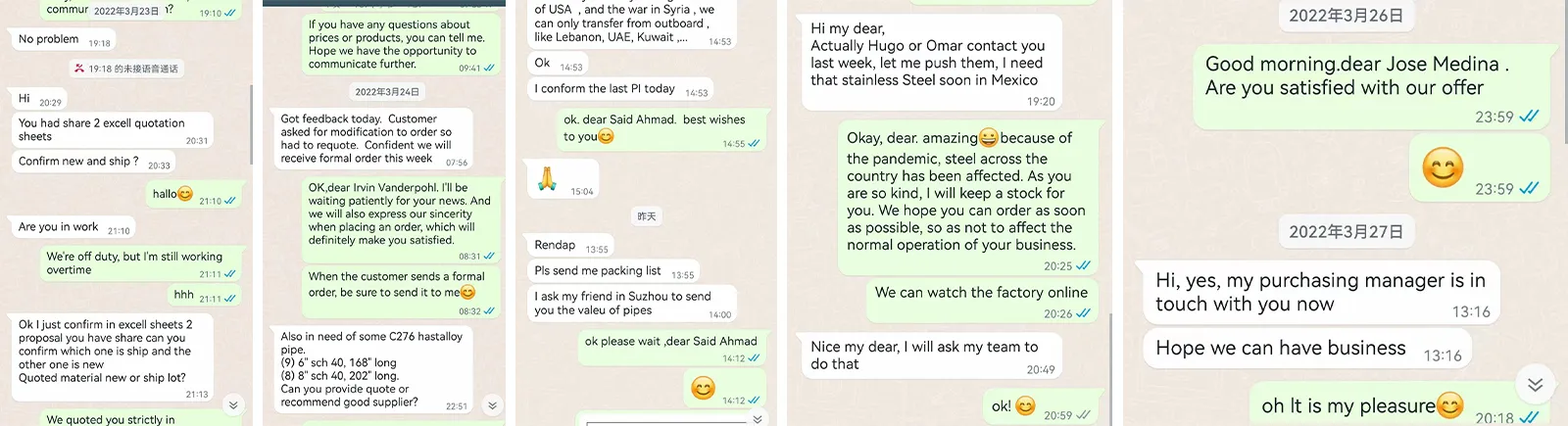

CUSTOMER VISIT

In ZYUAN, more than 180 steel grades have either been used to substitute import or produced with foreign standards, more than 30 steel grades have been exported many developed countries and regions in Europe, America and Asia, setting up mighty image of brand.

Customer photo

Customer photo

Customer photo

Customer photo

Customer photo

Customer photo

FACTORY WORKSHOP

ZYUAN STEEL GROUP CO.,LTD has been founded over 20 years. And ZYUAN has 12 product series, 300 and more steel grades, 400 and more thickness specifications steel pipes, sheet, coils and other products such as low alloy high strength steel products and alloy structural steel products etc.

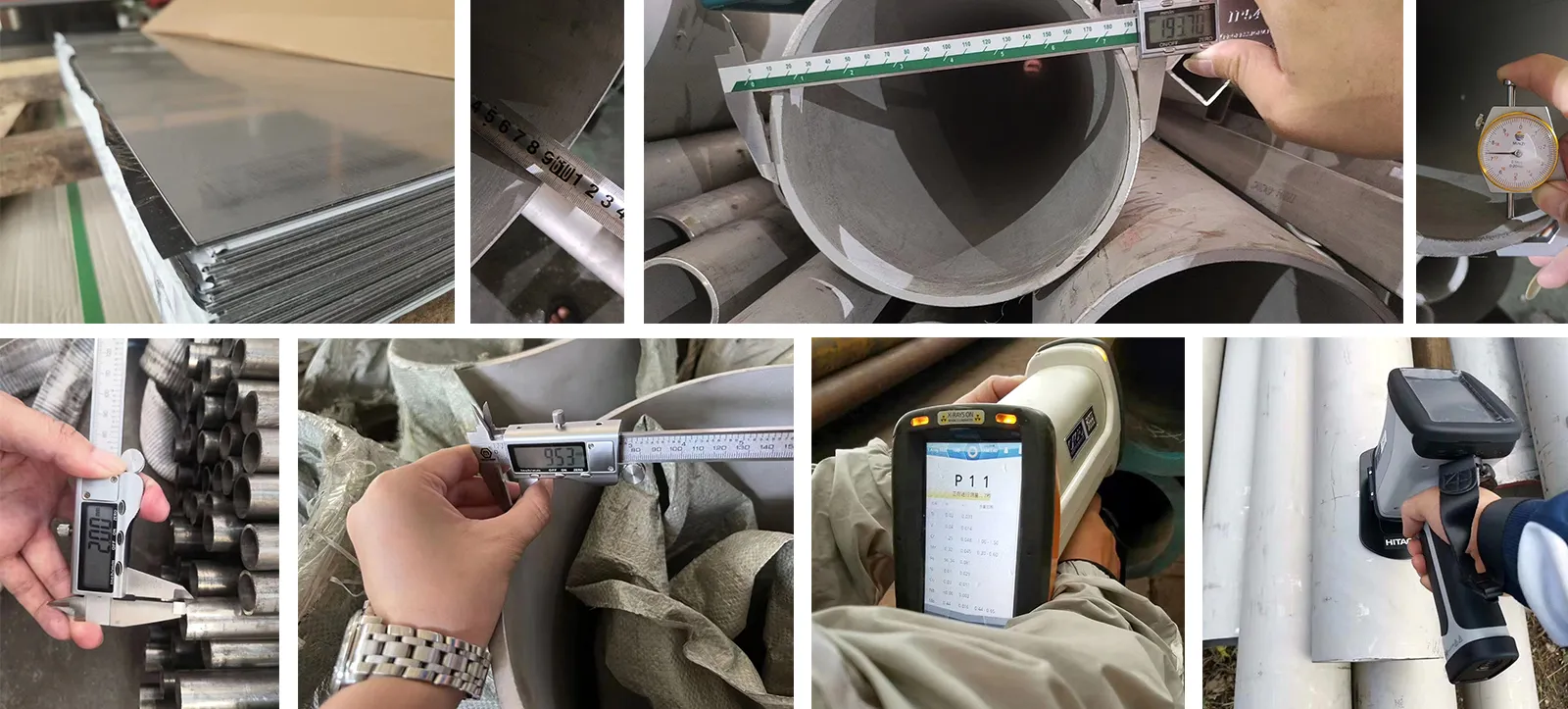

TEST

ZYUAN STEEL GROUP CO.,LTD has been founded over 20 years. And ZYUAN has 12 product series, 300 and more steel grades, 400 and more thickness specifications steel pipes, sheet, coils and other products such as low alloy high strength steel products and alloy structural steel products etc.

TEST

ZYUAN STEEL GROUP CO.,LTD has been founded over 20 years. And ZYUAN has 12 product series, 300 and more steel grades, 400 and more thickness specifications steel pipes, sheet, coils and other products such as low alloy high strength steel products and alloy structural steel products etc.

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE